News

- 2022-07-02 17:01:38

-

For those who know UL standards, they should know that there are great differences between UL's wire and cable standards and IEC and GB standards in terms of product structure and test methods. UL subject 758 standard is a technical document of UL company. In order to make everyone better understand the content and use it to guide production or trade production activities, we will briefly introduce the content of UL subject 758 here

UL subject758 introduction

We often see the abbreviation of AWM, which refers to the English abbreviation of appliance wiring material. The application scope of the products involved in the technical document: the electrical lead wire products included in the UL product catalogue are components (components) or connecting cables used for factory assembly, as well as other occasions that UL company confirms can be used. This technical document contains wires with single core and multi-core structures, which have a variety of conductor specifications, insulation thickness, and different materials and uses. Products with special purposes usually have special purpose marks on their labels, reels or packaging boxes. Through the UL approval mark [brother] pasted on the label, reel or smallest unit packaging box, we can identify whether the products are produced under UL approval and post supervision

Type of appliance wiring materialstyles

The technical document contains more than 8250 kinds of electrical wiring materials (AWM), each of which has a corresponding number, such as style 1015, etc., in which the number of cores ranges from single core wires to 150 core or more cables. Among them, the minimum rated temperature is 60 degrees, the maximum is 500 degrees, the minimum rated voltage is AC 30V, and the maximum is AC 60000v. UL divides AWM into 5 parts, numbered from 1 to 5, according to whether the conductors of various types of AWM are single core tapes or multi-core, and whether the insulation, sheath or covering layer is thermosetting material or thermoplastic material. Appliance wire numbering system

Number of types (styles) of part number AWM

1: Single core conductor, thermoplastic insulation, 999 styles

2: Multi core conductor, thermoplastic insulation, 999 styles

3: Single core conductor, thermosetting material insulation, 616 styles

4: Multi core conductor, thermosetting material insulation, 464 styles

5: The special types of single core and multi-core conductors have 349 styles

10: The continuation of Part 1 has 355 styles

20: The continuation of Part 2 has 996 styles

Once the AWM category is divided into part numbers, UL will add several type numbers after its part number. If there are no more than 1000 types of AWM in a part, its total number has 4 digits; If there are more than 1000 types of AWM in a part, add a 0 after the part number. For example, there are more than 1000 AWM categories in part 2, so category 2999 is followed by category 20000. Since 1959, some new AWM categories have been added and some old AWM categories have been deleted, so some numbers have become empty Here are some examples:

(1) We are familiar with UL style 1015, which is No. 15 in part 1 of UL subject 758. From the leftmost "1" in "1015", we can know that it is part 1 of ulsubject 758, and from the last three, it is AWM of category 15. In ulstyle 1015, we can know the release time and modification time, the type of material used, temperature and voltage level, wire gauge size, insulation thickness and structural requirements, reference standards, UL post supervision and testing content, purpose and mark, etc. By analogy, UL style 1999 is No. 999 in part 1 of UL subject 758; Ulstyle 10300 is No. 1299 in part 1 of ulsubject 758.

(2) The category number of other parts: UL style 2032, this category is No. 32 in part 2 of UL subject 758, ulstyle 20995, this category is No. 1994 in part 2 of UL subject 758; Ulstyle 3028, which is No. 28 in part 3 of UL subject 758; Ulstyle 4135, which is No. 135 in part 4 of UJ subject 758; Ulstyle 5199, which is No. 199 in part 5 of UL subject 758, etc. Therefore, from the style number, we can know which part of the number (also known as the page in UL subject 758), such as ulstyle5199, which is called page 5199 in ulsubject 758

4. Type description page (stylepage)

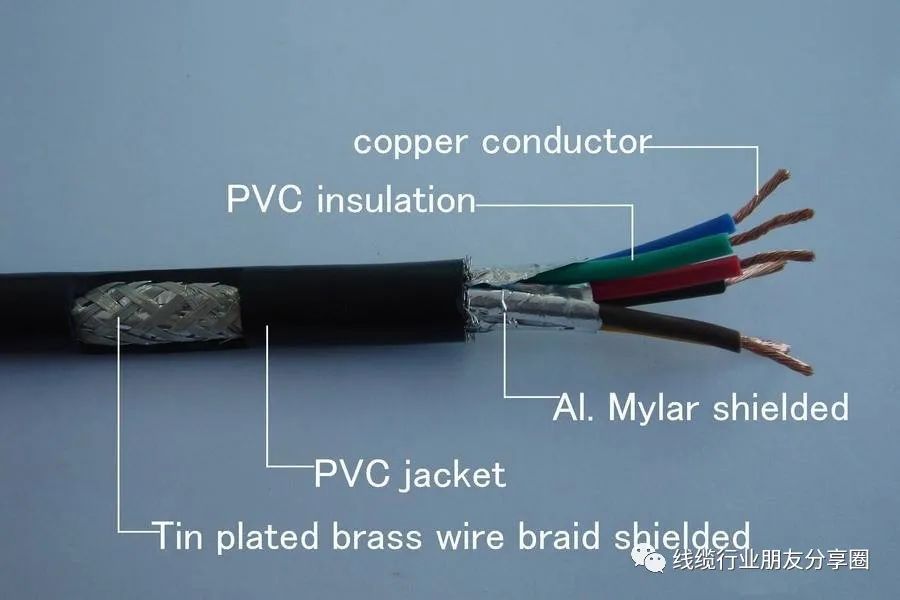

The first AWM wire or cable studied and approved by UL company is described in detail in its corresponding category description page. The contents in the category description page include: category number, comprehensive title, rated temperature, rated voltage, insulation material and thickness, conductor wire gauge and material, shielding (if used), special combustion requirements, cabling structure of multi-core type (style), material and thickness of covering layer and / or outer sheath, and statement of allowable scope of use The number of pages on the category description page is derived from the general guide in section subject758 of electrical wiring materials (AWM). If you want to get a copy and fax it to UL, you can get the style you want by paying a certain fee UL will add or modify 200 kinds of description pages every year. In January, 1998, all types in the electronic library were assigned the extended number ".1" to indicate the status of modification. If a category description page continues to be modified, its extended number will also change to ".2" ".3". For example, UL style 1015.1 and UL style 1015.2 are available on CD. UL style 1015.2 is a valid (modified) version of UL style 1015.

5. Requirements for electrical connecting materials (AWM)

UL company conducts research and inspection on AWM to determine whether it conforms to a certain rated voltage and temperature, and meets its application needs At present, there is no UL standard specifically applicable to AWM, only a series of UL bulletins about AWM. AWM applicable requirements and test methods also refer to some other UL standards, which are:

UL 13 low power limit wire and cable

UL 44 rubber insulated wire and cable

UL 62 cord and mounting wire

UL 493 thermoplastic insulated underground feeder and branch cables

UL 814 gas pipeline marking and ignition cable

UL 1063 wire and cable for machine tool

UL 4 armored cable

UL 719 non metallic sheathed cable

UL 1581 reference standard for wires, cables and flexible cords

UL subject 758 chapter general guidelines (refer to AWM documents)

UL has a total of more than 100 test items for AWM for various purposes. The basic test and research projects include: structural inspection and combustion test, as well as tensile strength, elongation, dielectric strength, bending test and conductor corrosion test. These test items are carried out on the samples that have not been aged and have been aged for 7-150 days in the circulating air aging box. AWM research projects also include: thermal shock, thermal deformation, cold bending and insulation resistance test. Some AWM category research projects also involve projects that depend on the insulation material and the purpose of AWM.

6. Rated voltage

One of the main factors determining the rated voltage of AWM is the insulation thickness. Generally, the rated voltage of AWM lead wire used for PVC insulation of internal lead wire is 300V if the conductor wire gauge is not more than 16awg and the insulation thickness is 15 mils. If the PVC insulated conductor wire gauge is larger or the external lead wire usually requires a minimum insulation thickness of 30 mils. If the wire gauge of PVC insulated conductor is 9awg or less and the insulation thickness is 30 mils, the rated voltage of AWM lead wire is 600V. AWG size is the measured mil circle of the conductor cross section. If a conductor is a solid core conductor, the diameter can be measured directly for calculation; For stranded conductors, AWG is the sum of the mils of each strand. There are some types of AWM lead wires that do not specify the rated voltage (NVA). These types include AWM with optical fiber structure and AWM with rated voltage that can only be evaluated after finished products.

7. Signs

Although UL has no requirements, AWM manufacturers can mark the company name, type number, rated temperature and rated voltage on the surface of wires and cables. For some types of AWM, UL requires each roll of products to be marked or labeled, indicating the rated voltage, manufacturer, manufacturing date, conductor size, conductor material (if not copper), product purpose, rated humidity and insulation thickness. The combination mark recognized by UL on AWM products is the certificate of the manufacturer, indicating that its AWM is produced under the requirements of UL. The UL approved combination mark also indicates that its products are made under the UL subscription combination mark and that its products are produced under the UL post supervision service procedure. The on-site representative of UL post supervision service decided that the AWM line was produced according to the type description page described in UL post supervision service procedure manual without notifying the factory at a specific time. During the visit, the on-site representative of UL also took samples and sent them to UL Laboratory for additional tests.

8. Optional VW-1 logo

AWM without outer sheath and covering layer insulated with FEP, TFE, PTFE or PFA automatically meets the requirements of VW-1 combustion test. For the requirements of combustion test in accordance with VW-1. For other types of AWM, if the composition of the insulation material used is suitable for the application range specified on page 95 of subject 758, it can be marked with "VW-1".

Comparison between ul1581-1997 and 1990 edition

Ul1581 is a basic standard for wires, cables and flexible cords, which includes special requirements for conductors, insulation, sheaths and other protective layers in standards such as rubber insulated wires and cables (UL 44), thermoplastic insulated wires and cables (UL 83), flexible wires and device wires (UL 62) and user incoming cables (UL 854), as well as sample preparation, sample selection, pretreatment methods, measurement and calculation methods. Compared with the 90 version, the current version adds the requirements for 8000 Series aluminum alloy conductors and copper-clad aluminum conductors. Add the test of sheath material for CATV cable. Add long-term aging test, that is, take a group of samples from the oven every 90, 120 and 150 days, measure their final elongation, and calculate the expected 300 day elongation value according to e (T) = e90e-r (T-90), which should not be less than 50%. Cancel the oxygen bomb and air bomb aging tests of all insulation and sheath materials. Add the content of mixture analysis, including the analysis of PVC mixture by infrared spectroscopy, ash measurement, elemental analysis and gel permeation chromatography. The mixture of nylon and TPE was analyzed by infrared spectroscopy, pyrolysis gas chromatography, thermogravimetry and differential scanning calorimetry. Add the expansion and foaming test after soaking of the round finished flexible cord, make five marks every 2m on the 32m long flexible cord sample, then wind it into a loose 600mm coil, soak it in tap water at 50 ± 1.0 ℃ for 14 days, and then loosen it after taking it out. If the average outside diameter increment (expansion) exceeds 20%, the requirements are not met. Add the horizontal sample combustion test of instrument wires, and cancel the horizontal sample combustion test and full wire combustion test of 24~22awg Christmas tree wires and flexible wires. Cancel the impact resistance, wear resistance and bending flexibility tests of elevator cables, and cancel the torsion fatigue test of flexible cords for heaters

Introduction to professional UL testing and Certification Commission

About youer testing certification

Founded in 2009, ycct has two international testing laboratories and five branches in Ji'an, Shenzhen, Suzhou, Chengdu and Huizhou, with an office and laboratory area of more than 25000 square meters and more than 800 sets of advanced testing instruments and equipment.

Since its establishment, youer testing has been certified by more than 10000 enterprises from around the world (including (1) Huawei, Samsung, HP, Dell, Foxconn, Philips, BYD, Ricoh, brother, Desai and other end customers; (2) Hengtong, AVIC Baosheng, Nanyang, Pudong, Jinbei, Changfei, tefa, sun, Huaxun, Zhaolong, jinhuanyu, dongjiaxin, Hehong and other cable customers; (3) Jinfa, CGNPC, Wanma, Yizhou, Yinxi, Qinghu and other rubber and plastic material customers; (4) Haolishi, Liangwei, Eaton, baideli, Liyuan, Yijun, yifuwan, Licheng, Xikang, Qifeng and other plug and socket power line customers; (5) MOLEX, Amphenol, odaco, Derun, qiaoheli and other electronic parts customers; (6) Nanya, Jiantao, Shengyi, Shenghong, Lianneng, Jinghua, intercontinental and other PCB customers) provide diversified and systematic testing technology, product certification and global safety regulation training services.

With the business philosophy of "standard guidance, fair public welfare, teaching to dispel doubts, and safeguarding safety", youer testing and certification advocates the code of conduct of "unified standards, unified methods, and unified judgment", takes "making consumers use it more safely" as its own responsibility, and relies on the comprehensive testing ability of the laboratory and the leading global standard interpretation ability to serve thousands of enterprises, with more than 35000 trainees nationwide, Assist and guide the products of major enterprises to obtain international and domestic product certification and test reports. Our mission is to make products more safe and reliable, and make made in China better go to the world!

Youer testing innovation industry Incubation Park

(Ji'an, Jiangxi)

Youer testing certification innovation industry Incubation Park is located in Ji'an national high tech Industrial Development Zone, with a construction area of 25000 square meters. Youer testing innovation industry Incubation Park is a modern industrial service complex integrating testing public service platform, electronic information industry supply chain headquarters base, electronic information industry entrepreneur club and Chinese professional skills training, serving customers from all over the world.

The comprehensive office building of youer testing, certification and innovation industry Incubation Park has a total of 12 floors, with each floor of 1100 square meters. At the same time, the park has a logistics storage center of 30000 square meters and more than 100 innovative talent apartments, which can be settled in more than 50 enterprises related to the supply chain of wire and cable and electronic information industry.

At present, there are Zhejiang Wanma group, Wuxi Zhongding, Langfang Cuishi materials, Dongguan Yuehua, Hangzhou magic cube, Dongguan Congmo, Guangzhou Yingsu, Dongguan Lamu, Fei radium laser, Ji'an Haichen finance, Guangyuan group, Dongguan haodengxin, Changhong cable, Zhongshan huazi cable, Dongguan youze, Guangdong Rijin intelligent equipment, Dongguan yihengte, Wuxi Muxu, Dongguan Yuehua, Shenzhen Ruisheng technology Kunshan Jierong signed contracts with 19 supply chain enterprises of wire and cable and electronic information industry to jointly build the country's only "China's electronic information industry supply chain headquarters base". Welcome more supply chain enterprises from all over the country, such as materials, molds, production equipment, testing equipment, molds, auxiliary materials, to settle in for common development and resource sharing.

Youer testing South China Testing Center

(Shiwan, Huizhou)

Youer testing and certification South China Testing Center is one of the largest global combustion testing centers for wires and cables in South China. We have built a domestic leading large-scale Combustion Laboratory for wires and cables (North American ul1685/csa FT4 tray bundle combustion, European CPR heat release bundle combustion, optical cable (IEC, GB, EN) ordinary bundle combustion, fire resistance (BS, IEC, GB), smoke density, low smoke, halogen-free, oxygen index, American standard and national standard single vertical combustion, etc.). At the same time, we have a full set of imported equipment to provide you with rohs2.0, reach, cp65, PAHs and other environmental protection tests.

- [Return Home] [Print] [Go Back] Next

Contact Us

Contact Person:

Julia ZhuTel:

17706681893Fax:

E-mail:

sales@plug9.com

Products Search

Brand Zone